Click to learn about the relevant content about snail horn faults

Source of articles:www.tembdq.com

Release time:2026/1/4 14:32:40

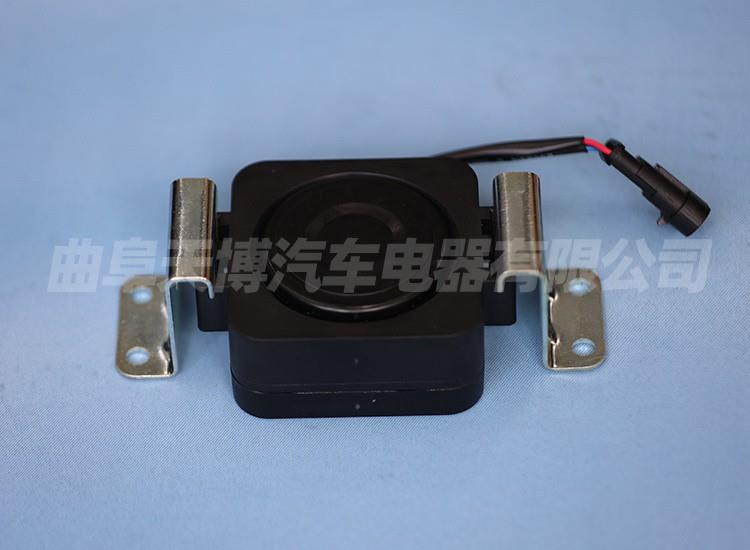

We know that all cars have horns on them. Although some people may not like to use them, they will always be useful. It is a must-have product on cars, and it can be used without it, but it cannot be used without it. Nowadays, many cars use snail horns, which are very convenient to use. However, sometimes there may be some minor malfunctions. So, how much do you know about these malfunctions? Do you know how the snail horn works? Next, the editor will take everyone to take a look!

When the horn button on the steering wheel or elsewhere is pressed, the current from the battery will flow through the circuit to the electromagnetic coil of the horn relay. The electromagnetic coil will attract the dynamic contact switch of the relay to close, and the current will flow to the horn. The current causes the electromagnet inside the horn to work, causing the diaphragm to vibrate and produce sound.

Line malfunction:

The main faults in the horn circuit are virtual connections, such as loose horn plug terminals, burnt horn relay contacts, and poor horn switch contacts.

Snail horn itself malfunction:

But in many horn malfunctions, especially in winter, the most common problem is the malfunction of the horn itself. Considering factors such as usage environment, the main causes of speaker malfunctions are as follows:

Contact erosion: If the horn is pressed for a long time, it is easy to cause the horn contact to burn and produce impedance. The current flowing through the electromagnetic coil weakens, and the electromagnetic suction force decreases, which cannot attract the armature to drive the diaphragm to vibrate normally, resulting in hoarse or even no sound. But when the horn is constantly honked, if a strong current passes through the impedance in an instant, it can still work normally, so it can be good or bad at times.

Poor sealing can easily cause moisture damage: Although the interior of the horn is sealed, if it is not sealed properly, it can easily cause moisture damage to the contacts and prevent them from working properly due to the presence of fog or water vapor in the air during car washing.

Poor contact of electromagnetic coil terminals: Some horn internal electromagnetic coil enameled wire terminal joints are connected by aluminum metal rivet crimping, which is not a reliable welding connection. If the insulation paint on the end enameled wire is not cleaned or the rivet crimping is not secure, it is easy to cause virtual connection faults, resulting in poor horn operation. This type of malfunction is due to the quality of the speaker and cannot be repaired. Only new parts can be replaced.

Precautions for using snail horn:

1. When washing the car, remember to prevent the horn from getting wet. If the horn is found to have water ingress, use an air gun to blow it dry as soon as possible.

2. Try not to always honk the horn for a long time, as this can easily cause premature burning of the horn contacts.

3. If the horn malfunctions, try to seek the help of professional maintenance technicians. First, determine whether it is a circuit fault or a fault with the horn itself. Do not blindly replace the horn, as it may cause unnecessary waste.

That's all for today's sharing about the snail horn. I hope it's helpful to you. If you have any further questions, you can log in to our official website to contact our staff, or leave a message directly in the station. Our staff will definitely answer all your questions in a timely manner. Thank you for reading.