Oxidation treatment helps you solve the problem of clutch spring corrosion

Source of articles:www.tembdq.com

Release time:2026/1/4 15:24:28

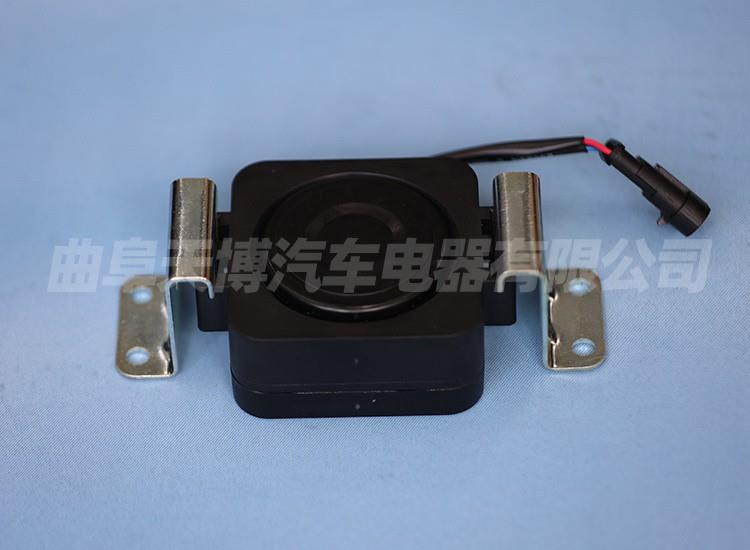

The clutch spring is a component installed on the car clutch, which plays a role in buffering and balancing, helping to ensure safe driving of the car and reducing impact force. When the clutch spring is used for a long time, corrosion may occur sometimes. Don't worry, there are ways to help remove corrosion. We can oxidize the spring, which can generate protective magnetic iron oxide on the surface of the spring to protect the clutch spring.

The alkaline oxidation method involves immersing the clutch spring in a sodium hydroxide solution containing an oxidizing agent at a temperature of around 140 ℃ for a period of time. The oxidizing agent and sodium hydroxide react with iron to produce sodium ferrocyanide and sodium ferrite, which then react with each other to produce magnetic iron oxide.

The thickness of the oxide film layer is about 0.6-2/μ m. Although oxide film can improve the corrosion resistance of clutch springs, its protective ability is poor due to its thin film and pores, and it can only be used for clutch springs working in media with low corrosiveness. The level of its anti-corrosion performance depends on the density and thickness of the oxide film, which in turn determines factors such as the concentration of sodium hydroxide and oxidant used in the oxidation treatment, as well as the temperature of the solution.

In order to improve the corrosion resistance and lubrication ability of the oxide film, it is necessary to strengthen the treatment before and after oxidation treatment. Before oxidation treatment, the rust, oxide scale, oil stains, heat treated salt residue, and surface contact copper layer on the surface of the clutch spring must be thoroughly removed. After oxidation treatment, the clutch spring is usually filled with soap solution or dichromate solution, then washed, dried or dried with running warm water, and then coated with a water film to replace rust proof oil or a specific temperature of mechanical oil for oil immersion treatment.

Traditional oxidation treatment requires heating. In recent years, some manufacturing units have used room temperature blackening agents, which overcome the shortcomings of traditional blackening processes and save a lot of energy.

The operation process of blackening agent is relatively simple, and its process route is: degreasing, rinsing, acid washing, rinsing, blackening (2-5 minutes at room temperature), rinsing, and water film replacement of rust proof oil. It should be noted that the oil on the middle clutch spring workpiece must be completely removed and cleaned before being placed in room temperature blackening agent for oxidation treatment.

The above is all the content we have shared with you. We believe that after reading this article, you have gained a deeper understanding of the oxidation treatment methods for clutch springs; If you have any further questions, you can call us anytime and our staff will provide you with answers one by one.