Analyze the principle and structure of snail horn

Source of articles:www.tembdq.com

Release time:2026/1/4 15:29:19

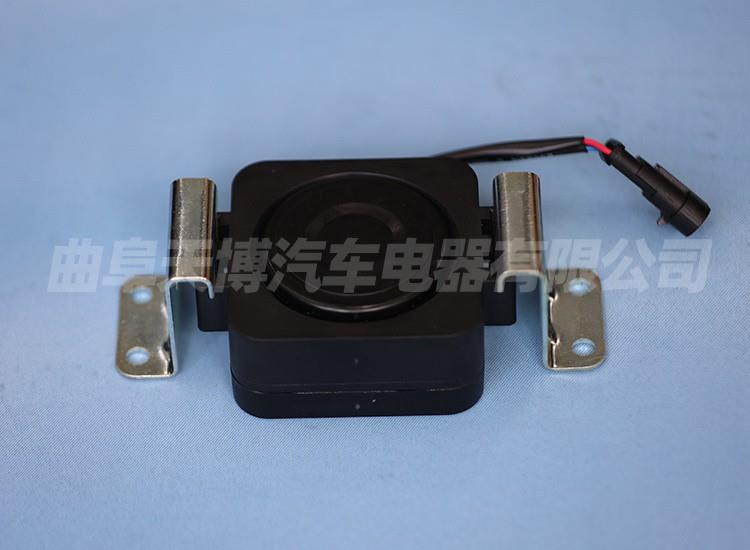

When it comes to snail horns, some friends may feel unfamiliar with them. This is a new type of horn that has been improved based on the horn and is mainly used in car mounted vehicles. After using the snail speaker, the sound quality will be clearer and the volume will become larger. Compared to ordinary speakers, there are many advantages. In the following article, we have compiled some working principles and structural components of snail horns. Interested friends can take a look.

1. Although the snail speaker may seem simple, it is of better quality than ordinary speakers. It is an upgraded version of an ordinary speaker, with an additional snail shaped auxiliary chamber added to make the sound quality clearer and increase the volume. The advantage of snail horn is that it is often used to warn drivers who are approaching quickly. Its warning signal allows the opposing driver to estimate the distance and direction of the vehicle that issued the warning sound. Both production and materials are made of high-quality materials, so they are all-weather, salt resistant, and able to resist the impact of coarse sand and stone fragments, and can adapt to various weather conditions.

2. The signal generation method is pulse pressure. The sound transmission is more harmonious in a diffuse fan-shaped divergent transmission. The sound waves of the snail horn are scattered from the exit of the horn to both sides, so the sound emitted by the snail horn is transmitted in a fan-shaped manner, and the sound is harmonious.

(When the driver presses the button switch, current passes through the coil through the contact point, and the coil generates magnetic force to pull down the armature and force the diaphragm steel plate to move. The movement of the armature breaks the contact point, and the magnetic force disappears when the current is interrupted. The diaphragm steel plate returns to its original position together with the armature under its own elasticity and the action of the spring plate. The contact point closes the circuit, and the current flows through the coil through the contact point to generate magnetic force, repeating the above action. The diaphragm continuously vibrates in this way, producing a sound. The resonance plate is rigidly connected to the diaphragm steel plate, which can make the vibration smooth and produce a more pleasant sound.)

3. The signal generation method is pulse pressure. The sound transmission of the snail horn in Rencheng District is relatively harmonious through a diffuse fan-shaped divergent transmission. The sound waves of the snail horn are scattered from the exit of the horn to both sides. Therefore, the sound emitted by the snail horn is transmitted in a fan-shaped manner, and the sound is harmonious. (When the driver presses the button switch, current passes through the coil through the contact point, and the coil generates magnetic force to pull down the armature and force the diaphragm steel plate to move. The movement of the armature breaks the contact point, and the magnetic force disappears when the current is interrupted. The diaphragm steel plate returns to its original position together with the armature under its own elasticity and the action of the spring plate. The contact point closes the circuit, and the current flows through the coil through the contact point to generate magnetic force, repeating the above action. This repeated cycle causes the diaphragm to continuously vibrate, thereby producing a sound. The resonance plate is rigidly connected to the diaphragm steel plate, which can make the vibration smooth and produce a more pleasant sound.)

Thank you for taking the time to read our article amidst your busy schedule. If you have any other questions or doubts that have not been answered, please feel free to contact our staff or leave a message on the website. We will periodically organize and share user questions with friends, and please continue to follow us.

- Next article:Cleaning tips for clutch springs

- Next article:Summary of knowledge on corrugated springs